1976 HERCULES WANKEL ROTARY, 3,782 ORIGINAL MILES, RUNS AND RIDES PERFECT

1976 Other Makes W-2000

Other Makes W-2000 1976 technical specifications | |

|---|---|

| Condition: | Used |

| Item location: | Chicago, Illinois, United States |

| Make: | Other Makes |

| Model: | W-2000 |

| Year: | 1976 |

| Mileage: | 3,782 |

| VIN: | 480005183 |

| Color: | Black |

| Vehicle Title: | Clear |

| You are interested? | Contact the seller! |

Description |

|---|

1976 HERCULES W-2000, ARE OIL INJECTED WANKEL ROTARY, LL ORIGINAL SURVIVOR, UNS AND RIDES AS NEW

1976 HERCULES W-2000, ARE OIL INJECTED WANKEL ROTARY, LL ORIGINAL SURVIVOR, UNS AND RIDES AS NEW

Frame Number: 480005183

Engine Number: 7587479

In the 1970’s, ith the rotary craze in full swing, he Hercules Motorcycle Company turned out two fantastic models of the W-2000 machine with the Wankel rotary engine. This is a later oil injected example. Please note that unlike any other Hercules rotary machines for sale, his one is in perfect running condition. The condition of this machine is completely original. Everything from the frame to the motor to the fenders is exactly the way it came from the factory. I believe I am the third owner from new, ut can’t be positive. This machine has been a part of my collection for some time and is ridden occasionally. The bike is stored in a temperature controlled environment throughout the entire year. PLEASE NOTE: This bike will be sold with a notarized bill of saleonly. It has never been titled in any state. Please see my termsbelow in the description section of the ad. I'm happy to help the new owner procure a title if he/she would like one after the sale. When I purchased this particular machine, t was in the condition you see in the photos, ut it did not run. I went through the entire machine and got everything working. All of the major engine, ransmission, nd braking components are operational. The tires are very nice and are the correct type and size for the Hercules. The brakes have also been completely rebuilt, ront and rear. The engine and transmission are original and are in perfect running condition. The bike is very easy to start. A new battery was also installed recently.

The paint is original and in very nice condition, onsidering the age of the machine. The seat is original and is also in very nice condition down to the pan, hich is also original. The Hercules on the road is very easy to handle, nd rides down the road tight, ith no shakes, himmies, r rattles. It shifts and accelerates smoothly and holds the road as it should. There is absolutely nothing that needs to be done to this machine to ride, how, nd enjoy it. The new owner will have a fantastic and incredibly rare original survivor machine that can be ridden and enjoyed as well as shown at any vintage motorcycle show. I have a rotary motorcycle collection made up of Hercules pre-mix and oil injected machines, s well as Suzuki RE-5s, o if you have specific rotary questions, ust want to learn more, r are looking for something in particular, lease let me know. I’m also always looking for interesting motorcycles to add to my collection, o if you have something interesting to share, lease contact me. TERMS: $500 DEPOSIT DUE WITHIN 48 HOURS OF AUCTION CLOSE. BALANCE OF AUCTION AMOUNT MUST BE PAID BY CASH IN PERSON, ANK TO BANK TRANSFER, R CERTIFIED FUNDS (WITH VERIFICATION) ONLY WITHIN 7 DAYS OF AUCTION CLOSE. SORRY, O C.O.D. AND NO PAYPAL.

PLEASE NOTE... This motorcycle will be sold with a bill of sale only, s it has never been titled in any state. I am also happy to notarize the bill of sale if requested. I will also cooperate with the buyer as much aspossible in order for a title to be procured. There are quite a few title services that advertise in publications such as Hemmings Motor News that specialize in titles for cars andmotorcycles in situations like this. I can also recommend a few I have dealt with in the past. It's a very easy process.

The description of this motorcycle is written to the best of my knowledge. However, am by no means an expert on Hercules motorcycles. Please don’t hesitate to ask for more photos and, f possible, ome and look in person before the auction ends. ALL SALES ARE FINAL! If you have any questions, lease contact me before the auction ends. If you have any questions, lease contact me. If you live close to Chicago, encourage you to come and inspect the Motorcycle in person. In an effort to protect the eBay user information and to help ensure the authenticity of correspondence between sellers and bidders, Bay’s new listing format does NOT display any bidder information. Nevertheless, STRONGLY encourage bidders to contact me directly to answer questions or to verify correspondence. Seller reserves the right to not accept bids or sell the vehicle to anyone with a zero or negative eBay feedback rating. This motorcycle is being sold as is, here is with no warranty, xpressed, ritten or implied unless there is a warranty in effect from the factory. The seller shall not be responsible for the correct description, uthenticity, enuineness, r defects herein, nd makes no warranty in connection therewith. No allowance or set aside will be made on account of any incorrectness, mperfection, efect or damage. Any descriptions or representations are for identification purposes only and are not to be construed as a warranty of any type. It is the responsibility of the buyer to have thoroughly inspected the motorcycle and to have satisfied himself or herself as to the condition and value and to bid based upon that judgment solely. The seller shall and will make every reasonable effort to disclose any known defects associated with this motorcycle at the buyer's request PRIOR to the close of sale. Seller assumes no responsibility for any statements regardless of any oral statements about the item. Please remember that your bid constitutes a legally binding contract to purchase this item. If you require an inspection, ave it done prior to bidding. I strongly encourage all bidders to inspect the motorcycle personally or enlist the services of a professional inspector prior to placing a bid. After the sale, nspections are not recognized as a contingency to completing your obligation to your winning bid. If there are any questions regarding the above terms, lease e-mail prior to bidding. Please do not waste my time or yours bidding on an item you do not intend to pay for. If you bid on this part and win, ou are expected to pay for the motorcycle and pick it up in a timely manner! I welcome ALL international bidders and am happy to assist with making shipping arrangements. I can also arrange crating for shipment on my end for a nominal extra charge. If you are an international buyer, understand it can take some time to arrange shipping, o I do not mind keeping the motorcycle for a longer period of time until pick up. Please contact me before the sale ends, f possible, o discuss the specifics. AGAIN, PLEASE NOTE... This motorcycle will be sold with a bill of sale only, as it has never been titled in any state. I am also happy to notarize the bill of sale if requested. I will also cooperate with the buyer as much aspossible in order for a title to be procured. There are quite a few title services that advertise in publications such as Hemmings Motor News that specialize in titles for cars andmotorcycles in situations like this. I can also recommend a few I have dealt with in the past. It's a very easy process. Thanks for your interest!For more on the Hercules motorcycle company and the W-2000 Rotary, lease read on past the photos…

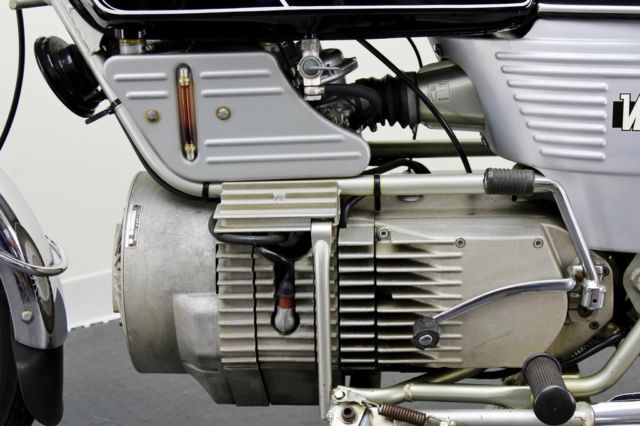

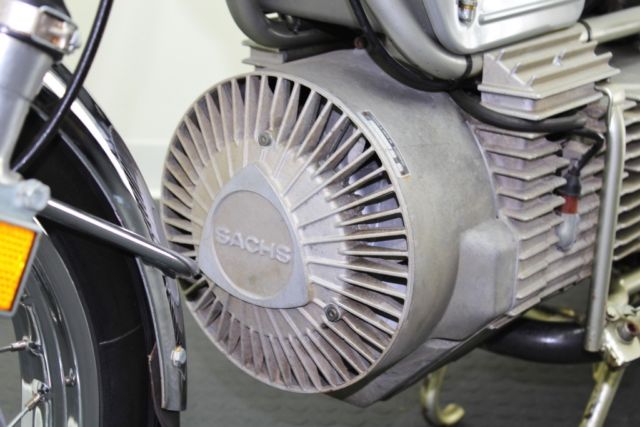

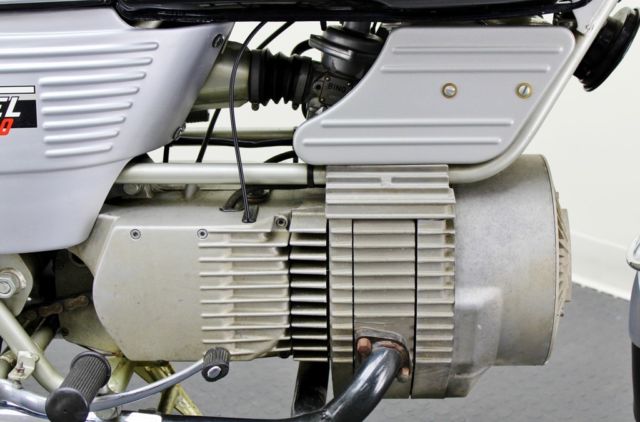

Hercules W-2000 Specifications: Engine: 294cc air-cooled single rotor Sachs Wankel, .5:1 compression ratio, 2hp @ 6,500rpm Top speed: 90mph Weight (dry): 381 lb (173kg) Price when new: $1,900History: Hercules was a brand of motorcycle manufactured in Germany until 1996. The Hercules Company was founded in 1886 and began producing motorcycles in 1904. It was merged with Zweirad Union after being purchased by ZF Sachs in 1963. In the 1950s and 1960s Sachs was the largest European fabricator of two-stroke motorcycle engines. Many of these engines were used in the Hercules line of small motorcycles, cooters and mopeds. In 1974 Hercules became the first company to offer a Wankel-engined motorcycle for sale to the general public. A prototype was first shown in 1970 at the West Cologne Fall Motorcycle Show to a mixed reception, nd the production bike was sold as a Hercules product except in the United Kingdom, here it was marketed as a DKW motorcycle. The W-2000 had a single-rotor air-cooled engine of 294cc that produced 23 hp, ater increased to 32 hp. Cooling was by a large fan placed in front of the engine (and the slipstream breeze while riding) and engine lubrication was by manually adding oil to the fuel in the tank. In 1976 Hercules launched the W-2000 Injection in which engine lubrication was from a separate oil tank via a pump. It had 18-inch wheels, front disc brake and a rear drum brake. According to a March 1976 review in Cycle World, he handling was good but the bike's low ground clearance limited its cornering ability. That review also declared the W-2000 to be a daily commuting bike, ot a sport motorcycle. Hercules introduced a rotary-powered dirt bike (the KC-30 GS Enduro) in May 1975, ut the model failed to sell due to its high price ($2,900). The Fichtel & Sachs single-rotor engine of 300 cc swept-volume as used in the Hercules – the only commercially available engine at the time – was used as a basis by BSA's project engineer David Garside in the early 1970s when designing a twin-rotor motorcycle engine of 600 cc, hich reached production as the "Norton Classic". The following is an excerpt from Motorcycle Classics… A Rare Machine: The Hercules W-2000 is referred to as the first mass-produced Wankel rotary-powered motorcycle. Envisaged in 1919 by German engineer Felix Wankel, he rotary power plant was thought by many to be an ideal engine. The Wankel rotary had far fewer moving parts than a four-stroke engine, nd was theoretically more efficient. But it wasn’t until 1957 that Wankel, orking with NSU, uilt his first running prototype rotary engine. The transportation industry took notice of this new engine; from aircraft manufacturers to automakers to motorcycle builders, veryone seemed interested in the new technology. One of the first to license the Wankel technology was Germany’s Fichtel & Sachs, t that time Europe’s largest producer of two-stroke engines. In the 1950s, erman motorcycle maker Hercules used Sachs lightweight two-stroke engines to power their many different motorcycles, opeds and scooters. Sachs purchased Hercules in 1963, nd eventually merged with the Zweirad Union, hich included the DKW brand. Hercules developed the W-2000 using the Sachs rotary engine in the late 1960s, nd a prototype machine was first shown at the 1970 West Cologne Fall Motorcycle Show. Reaction was mixed: “Should it be hailed as a great breakthrough, r a temporary mechanical diversion?” mused Dan Hunt in his opening paragraph about the prototype Hercules rotary in the January 1971 issue of Cycle World. According to the article, 0,000 of the 294cc Sachs rotary engines found in the prototype W-2000 had already been used in U.S.-produced snowmobiles, nd another version of the engine was used for powering small aircraft. In the prototype, ercules borrowed a 4-speed gearbox and shaft drive from a BMW R27 single. How the Rotary-Powered Motorcycle Works: When Hercules officially launched the W-2000 in 1974 (sold as a DKW in the U.K. because a bicycle manufacturer already had rights to the Hercules name), he BMW gearbox had been replaced with a 6-speed unit with chain final drive sourced from a Penton 400 dirt bike. A set of bevel gears transferred power from the rotary shaft through 90-degrees to the transmission mainshaft, nd the clutch was a seven-disc affair running in an oil bath. Of course, hat is of primary interest is the Sachs rotary engine, hich used a single spark plug firing a single rotor with apex seals. As explained in the May/June 2011 issue of Motorcycle Classics in an article about Suzuki’s RE-5 rotary-powered motorcycle (effectively identical in principle): “The rotor’s tips seal against the housing to form combustion chambers. Instead of a crankshaft, rotary uses an eccentric shaft with the rotor riding on the eccentric. A stationary gear on the end of the eccentric shaft keys the rotor to the eccentric shaft. Combustion pressure pushes the rotor away from the combustion face, ausing the eccentric shaft to rotate. The shaft’s eccentric defines the throw of the rotor while the stationary gear defines the rotor’s position on its axis. As the rotor spins, ts axis shifts, ausing the rotor to orbit and alter the combustion chamber for intake, ompression, gnition and exhaust phases.” When first introduced, he Sachs engine was rated at 23 horsepower, figure that was later improved to 32 horsepower. While listed at 294cc, or comparison to a piston engine that figure, n theory, hould be multiplied by two for a 588cc capacity: A single-rotor Wankel produces one power stroke every crank revolution, hereas a single-cylinder 4-stroke requires two crankshaft rotations for each power stroke. Fuel and air are mixed in a 32mm Bing carburetor, nd a single exhaust header splits into two under the engine and feeds two mufflers, ne on each side. Unlike the Suzuki RE-5, hich uses liquid-cooling to help dispel the great heat generated by a rotary, he Hercules W-2000 relies solely on a large axial fan at the front of the engine — and, f course, he cooling breeze of the slipstream once underway. The running gear consists of a tubular steel frame with twin front downtubes that bend back and run over the top of the engine. As a result, he Sachs rotary appears to hang from the frame, lthough it’s also supported at the rear. The front forks are Ceriani with 4.5 inches of travel, nd the rear swingarm is damped by adjustable preload Ceriani shocks. The Hercules wears 18-inch wheels at both the front and rear, nd the front brake is an 11.8-inch disc, hile the rear is a 7-inch drum. Period tests of the Hercules give the machine credit for its cornering stability, ut fault the 6.5-inch ground clearance as a major detractor in its cornering ability. “If it weren’t for the limited ground clearance,” Cycle World said in its March 1976 review, handling on the Hercules would far exceed the capabilities of the engine.” Cycle World said the W-2000 would burble along at an indicated 60mph, nd would climb a hill in sixth gear at 50 to 55mph, ut said it took at least one and most probably two downshifts to overtake a car on the highway: “…performance is not spectacular, ust adequate if the driver of the car you’re passing doesn’t stand on it at the same time. If he does, ou lose,” Cycle World said. Original distribution of the Hercules W-2000: While the W-2000 might well have been the first rotary-powered motorcycle offered publicly through a dealer network, e thinks it was built solely to test consumer acceptance of a rotary-powered two-wheeler. The first container of 40 Hercules W-2000s — 34 with red tanks and 6 with yellow — arrived in the U.S. in January 1975 and was delivered to Rotary Recycle U.S.A. The Rotary sales team visited dealers across the U.S., spousing the virtues of the Wankel. New dealers were enlisted, nd rising orders for the $1,900 rotary showed there was some interest. In May 1975, ercules introduced the KC-30 GS Enduro rotary-powered dirt bike, nd shipped two to Rotary Recycle. Although it generated great excitement, he KC-30’s $2,900 price tag killed any sales of the model. And by the end of summer, ales of the Hercules W-2000 had slowed to a trickle, erhaps because Hercules had announced an oil-injected model was coming for 1976. Early machines required pre-mixing the oil and gasoline. The W-2000 “Automix” are the 199 oil-injected 1976 machines produced. Of those 199, t is unknown how many landed in the U.S. Unlike the Suzuki RE-5, here is no crankcase oil used in the W-2000 engine, nd it does not run two-stroke oil. The RE-5 has five different cavities for four different fluids, he oil pump and the points are all running off of something else, nd the carburetor is a bit complicated. The Hercules, y comparison, s very simple, ith a fan in the front, nd the ignition runs off the same shaft. The Hercules sounds like a cross between a two-stroke and a four-stroke. On the road, ow-end torque is a bit lacking, ut with the 6-speed gearbox he can keep the W-2000 moving along on the highway. Just 1,784 of the rotary Hercules motorcycles were built, he plug being pulled not because they weren’t well made, ut because they missed their set monthly sales quota by 25 units. Hercules W-2000 press reports: “Surprisingly attractive in a Teutonic way, t is solidly built. The seating is comfortable and the handling is slow and graceful. It is hardly a sporting machine, or does it have sporting performance, ut it is flexible, mooth, omfortable and would undoubtedly prove a pleasure on extended journeys.” – Cycle World, anuary 1971 “It’s not one of those bikes that offer spirited performance. Speed is simply built up mile per hour by mile per hour. If you are over 4,000rpm, here really isn’t much advantage to shifting. And cornering is effectively limited by conservative ground clearance. So, he Wankel 2000 is not a bike for sport. It’s a bike for daily commuting.” – Cycle World, arch 1976 “Sixth gear at 65mph is perfect. But if you try to ease down to legal speed, he tach drops from 4,000 to about 3,200 and the engine gets rough. Gearing down doesn’t help, ut adding power does. You get the impression that the Hercules doesn’t agree with our politicians about how fast we should travel.” – Cycle, une 1976 Thanks to Motorcycle Classics and Cycle Magazine for the preceding articles and information… So what exactly is a rotary engine??? Check out the articles below to find out more... Wankel Engine: The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. Its four-stroke cycle takes place in a space between the inside of an oval-like epitrochoid-shaped housing and a rotor that is similar in shape to a Reuleaux triangle but with sides that are somewhat flatter. The very compact Wankel engine delivers smooth high-rpm power. It is commonly called a rotary engine, hough this name applies also to other completely different designs. The engine was invented by German engineer Felix Wankel. He received his first patent for the engine in 1929, egan development in the early 1950s at NSU, ompleting a working prototype in 1957. NSU then licensed the concept to companies around the world, hich have continued to improve the design. It is the only internal combustion engine invented in the twentieth century to go into production. Thanks to their compact design, ankel rotary engines have been installed in a variety of vehicles and devices including automobiles, otorcycles, acers, ircraft, o-karts, et skis, nowmobiles, hain saws, nd auxiliary power units. History: In 1951, he German engineer Felix Wankel began development of the engine at NSU Motorenwerke AG, here he first conceived his rotary engine in 1954 (DKM 54, rehkolbenmotor). The KKM 57 (the Wankel rotary engine, reiskolbenmotor) was constructed by NSU engineer Hanns Dieter Paschke in 1957 without the knowledge of Felix Wankel, ho remarked “you have turned my race horse into a plow mare“. The first working prototype DKM 54 was running on February 1, 957 at the NSU research and development department Versuchsabteilung TX. It produced 21 horsepower; unlike modern Wankel engines, oth the rotor and the housing rotated. In 1960 NSU (the firm the inventor worked for) and the US firm Curtiss-Wright signed an agreement where NSU would concentrate on the development of low and medium powered Wankel engines and Curtiss-Wright would develop high powered Wankel Engines, ncluding aircraft engines of which Curtiss-Wright had decades of experience in the design and production of. Considerable effort went into designing rotary engines in the 1950s and 1960s. They were of particular interest because they were smooth and quiet running, nd because of the reliability resulting from their simplicity. An early problem of buildup of cracks in the epitrochoid surface was solved by installing the spark plugs in a separate metal piece instead of screwing them directly into the block. A later alternative solution to spark plug boss cooling was provided by variable coolant velocity scheme for water-cooled rotaries which has had widespread use and was patented by Curtiss-Wright, ith the last-listed for better air-cooled engine spark plug boss cooling. These approaches did not require a high conductivity copper insert but did not preclude the use. Among the manufacturers signing licensing agreements to develop Wankel engines were Alfa Romeo, merican Motors, itroen, ord, eneral Motors, ercedes-Benz, issan, orsche, olls-Royce, uzuki, nd Toyota. In the United States, n 1959 under license from NSU, urtiss-Wright pioneered improvements in the basic engine design. In Britain, n the 1960s, olls Royce Motor Car Division pioneered a two-stage diesel version of the Wankel engine. Also in Britain, orton Motorcycles developed a Wankel rotary engine for motorcycles, ased on the Sachs air-cooled Wankel that powered the DKW/Hercules W-2000 motorcycle, hich was included in their Commander and F1; Suzuki also made a production motorcycle with a Wankel engine, he RE-5, here they used ferrotic alloy apex seals and an NSU rotor in a successful attempt to prolong the engine’s life. In 1971 and 1972 Arctic Cat produced snowmobiles powered by 303 cc Wankel rotary engines manufactured by Sachs in Germany. Deere & Company designed a version that was capable of using a variety of fuels. The design was proposed as the power source for United States Marine Corps combat vehicles and other equipment in the late 1980s. Mazda and NSU signed a study contract to develop the Wankel engine in 1961 and competed to bring the first Wankel powered automobile to market. Although Mazda produced an experimental Wankel that year, SU was first with a Wankel automobile on sale, he sporty NSU Spider in 1964; Mazda countered with a display of two and four rotor Wankel engines at that year’s Tokyo Motor Show. In 1967, SU began production of a Wankel-engined luxury car, he Ro 80. However, roblems with apex seal wear led to frequent engine failure, hich led to large warranty costs for NSU, nd curtailed further Wankel engine development. Mazda, owever, laimed to have solved the apex seal problem, nd was able to run test engines at high speed for 300 hours without failure. After years of development, azda’s first Wankel engine car was the 1967 Cosmo 110S. The company followed with a number of Wankel (“rotary” in the company’s terminology) vehicles, ncluding a bus and a pickup truck. Customers often cited the cars’ smoothness of operation. However, azda chose a method to comply with hydrocarbon emission standards that, hile less expensive to produce, ncreased fuel consumption, ust before a sharp rise in fuel prices. Mazda later abandoned the Wankel in most of their automotive designs, ut continued using it in their RX-7 sports car until August 2002 (RX-7 importation for Canada ceased with only the 1993 year being sold. The USA ended with the 1994 model year with remaining unsold stock being carried over as the ‘1995’ year.). The company normally used two-rotor designs, ut the 1991 Eunos Cosmo used a twin-turbo three-rotor engine.In 2003, azda introduced the Renesis engine with the RX-8. The Renesis engine relocated the ports for exhaust and intake from the periphery of the rotary housing to the sides, llowing for larger overall ports, etter airflow, nd further power gains. Early Wankel engines had also side intake and exhaust ports, ut the concept was abandoned because of carbon buildup in ports and side of rotor. The Renesis engine solved the problem by using a keystone scraper side seal. The Renesis is capable of delivering 238 hp (177 kW) with better fuel economy, eliability, nd environmental friendliness than previous Mazda rotary engines, ll from a nominal 1.3 L displacement, owever this was not enough to keep up with ever more stringent emissions standards. Mazda ceased production of their Wankel engine in 2012 after the engine failed to meet the Euro 5 emission standard. In 1961, he Soviet research organization of NATI, AMI and VNIImotoprom started experimental development, nd created experimental engines with different technologies. Soviet automobile manufacturer AvtoVAZ also experimented with the use of Wankel engines in cars but without the benefit of a license. In 1974 they created a special engine design bureau, hich in 1978 designed an engine designated as VAZ-311. In 1980, he company started delivering Wankel-powered VAZ-2106s (VAZ-411 engine with two-rotors) and Ladas, ostly to security services, f which about 200 were made. The next models were the VAZ-4132 and VAZ-415. Aviadvigatel, he Soviet aircraft engine design bureau, s known to have produced Wankel engines with electronic injection for aircraft and helicopters, hough little specific information has surfaced. Although many manufacturers licensed the design, ncluding Citroën with their M35 and GS Birotor, sing engines produced by Comotor, eneral Motors, hich seems to have concluded that the Wankel engine was slightly more expensive to build than an equivalent reciprocating engine, lthough claiming having solved the fuel economy issue, ut failed in obtaining acceptable exhaust emissions, nd Mercedes-Benz which used it for their C111 concept car, nly Mazda has produced Wankel engines in large numbers. American Motors (AMC) was so convinced “…that the rotary engine will play an important role as a powerplant for cars and trucks of the future…”, ccording to Chairman Roy D. Chapin Jr., hat the smallest U.S. automaker signed an agreement in February 1973, fter a year’s negotiations, o build Wankels for both passenger cars and Jeeps, s well as the right to sell any rotary engines it produces to other companies. The automaker’s President, illiam Luneburg, id not expect dramatic development through 1980, ut Gerald C. Meyers, MC’s Vice-President of the Product (Engineering) Group, uggested that AMC would be buying the engines from Curtis-Wright before developing its own Wankel engines and predicted a total transition to rotary power by 1984. Plans called for the engine to be used in the AMC Gremlin, ut development was pushed back. American Motors designed the unique Pacer around the engine, ven though by 1974, MC had decided to buy the Wankel engines from GM instead of building them itself. However, M’s engines had not reached production when the Pacer was to hit the showrooms. Part of the demise of this feature was the 1973 oil crisis with rising fuel prices, nd also concerns about proposed US emission standards legislation.

General Motors did not succeed in having a Wankel engine meeting both the emission requirements and having good fuel economy, o in 1974 the company canceled its development, lthough GM claimed having solved the fuel economy problem and having obtained engines with a duration above 530,000 miles; unfortunately they just published a few papers on the results of their research. This meant the Pacer had to be reconfigured to house AMC’s venerable AMC Straight-6 engine with rear-wheel drive. Design: In the Wankel engine, he four strokes of a typical Otto cycle occur in the space between a three-sided symmetric rotor and the inside of a housing. The expansion phase of the Wankel cycle is much longer than that of the Otto cycle. In the basic single-rotor Wankel engine, he oval-like epitrochoid-shaped housing surrounds a rotor which is triangular with bow-shaped flanks (often confused with a Reuleaux triangle, three-pointed curve of constant width, ut with the bulge in the middle of each side a bit more flattened). The theoretical shape of the rotor between the fixed corners is the result of a minimization of the volume of the geometric combustion chamber and a maximization of the compression ratio, espectively. The symmetric curve connecting two arbitrary apexes of the rotor is maximized in the direction of the inner housing shape with the constraint that it not touch the housing at any angle of rotation (an arc is not a solution of this optimization problem). The central drive shaft, alled the eccentric shaft or E-shaft, asses through the center of the rotor and is supported by fixed bearings. The rotors ride on eccentrics (analogous to cranks) integral to the eccentric shaft (analogous to a crankshaft). The rotors both rotate around the eccentrics and make orbital revolutions around the eccentric shaft. Seals at the corners of the rotor seal against the periphery of the housing, ividing it into three moving combustion chambers. The rotation of each rotor on its own axis is caused and controlled by a pair of synchronizing gears. A fixed gear mounted on one side of the rotor housing engages a ring gear attached to the rotor and ensures the rotor moves exactly 1/3 turn for each turn of the eccentric shaft. The power output of the engine is not transmitted through the synchronizing gears. The force of gas pressure on the rotor (to a first approximation) goes directly to the center of the eccentric, art of the output shaft. The best way to visualize the action of the engine in the animation at left is to look not at the rotor itself, ut the cavity created between it and the housing. The Wankel engine is actually a variable-volume progressing-cavity system. Thus there are 3 cavities per housing, ll repeating the same cycle. Note as well that points A and B on the rotor and e-shaft turn at different speed, oint B moves 3 times faster than point A, o that one full orbit of the rotor equates to 3 turns of the e-shaft. As the rotor rotates and orbitally revolves, ach side of the rotor is brought closer to and then away from the wall of the housing, ompressing and expanding the combustion chamber like the strokes of a piston in a reciprocating engine. The power vector of the combustion stage goes through the center of the offset lobe. While a four-stroke piston engine makes one combustion stroke per cylinder for every two rotations of the crankshaft (that is, ne-half power stroke per crankshaft rotation per cylinder), ach combustion chamber in the Wankel generates one combustion stroke per driveshaft rotation, .e. one power stroke per rotor orbital revolution and three power strokes per rotor rotation. Thus, ower output of a Wankel engine is generally higher than that of a four-stroke piston engine of similar engine displacement in a similar state of tune; and higher than that of a four-stroke piston engine of similar physical dimensions and weight. Wankel engines also generally have a much higher redline than a reciprocating engine of similar power output. This is in part because the smoothness inherent in circular motion, ut especially because they do not have highly stressed parts such as a crankshaft or connecting rods. Eccentric shafts do not have the stress-raising internal corners of crankshafts. The redline of a rotary engine is limited by wear of the synchronizing gears. Hardened steel gears are used for extended operation above 7000 or 8000 rpm. Mazda Wankel engines in auto racing are operated above 10,000 rpm. In aircraft they are used conservatively, p to 6500 or 7500 rpm. However, s gas pressure participates in seal efficiency, unning a Wankel engine at high rpm under no load conditions can destroy the engine. National agencies that tax automobiles according to displacement and regulatory bodies in automobile racing variously consider the Wankel engine to be equivalent to a four-stroke engine of 1.5 to 2 times the displacement; some racing series ban it altogether. Engineering: Felix Wankel managed to overcome most of the problems that made previous rotary engines fail by developing a configuration with vane seals that had a tip radius equal to the amount of “oversize” of the rotor housing form, s compared to the theoretical epitrochoid, o minimize radial apex seal motion plus introducing a cylindrical gas-loaded apex pin which abutted all sealing elements to seal around the 3 planes at each rotor apex. Rotary engines have a thermodynamic problem not found in reciprocating four-stroke engines in that their “cylinder block” operates at steady state, ith intake, ompression, ombustion, nd exhaust occurring at fixed housing locations for all “cylinders”. In contrast, eciprocating engines perform these four strokes in one chamber, o that extremes of “freezing” intake and “flaming” exhaust are averaged and shielded by a boundary layer from overheating working parts. The boundary layer shields and the oil film act as thermal insulation, eading to a low temperature of the lubricating film (max. ~200 °C/400 °F) on a water-cooled Wankel engine. This gives a more constant surface temperature. The temperature around the spark plug is about the same as the temperature in the combustion chamber of a reciprocating engine. With circumferential or axial flow cooling, he temperature difference remains tolerable. Four-stroke reciprocating engines are less suitable for hydrogen. The hydrogen can misfire on hot parts like the exhaust valve and spark plugs. Another problem concerns the hydrogenate attack on the lubricating film in reciprocating engines. In a Wankel engine, his problem is circumvented by using a ceramic apex seal against a ceramic surface: there is no oil film to suffer hydrogenate attack. The piston shell must be lubricated and cooled with oil. This substantially increases the lubricating oil consumption in a four-stroke hydrogen engine. Materials: Unlike a piston engine, here the cylinder is cooled by the incoming charge after being heated by combustion, ankel rotor housings are constantly heated on one side and cooled on the other, eading to high local temperatures and unequal thermal expansion. While this places high demands on the materials used, he simplicity of the Wankel makes it easier to use alternative materials like exotic alloys and ceramics. With water cooling in a radial or axial flow direction, ith the hot water from the hot bow heating the cold bow, he thermal expansion remains tolerable.Sealing: Early engine designs had a high incidence of sealing loss, oth between the rotor and the housing and also between the various pieces making up the housing. Also, n earlier model Wankel engines carbon particles could become trapped between the seal and the casing, amming the engine and requiring a partial rebuild. It was common for very early Mazda engines to require rebuilding after 50,000 miles (80,000 km). Further sealing problems arise from the uneven thermal distribution within the housings causing distortion and loss of sealing and compression. This thermal distortion also causes uneven wear between the apex seal and the rotor housing, uite evident on higher mileage engines. The problem is exacerbated when the engine is stressed before reaching operating temperature. However, azda Wankel engines have solved these problems. Current engines have nearly 100 seal-related parts. The problem of clearance for hot rotor apexes passing between the axially closer side housings in the cooler intake lobe areas was dealt with by using an axial rotor pilot, adially inboard of the oils seals plus improved inertia oil cooling of the rotor interior ( C-W patents 3,261,542, . Jones, /8/63, 176,915, . Bentele, .Jones. A.H. Raye. 7/2/62), nd slightly “crowned” apex seals (Different height in the center and in the extremes of seal). Motorcycle Engines: The world’s first Wankel-engined motorcycle was the 1960 IFA/MZ ‘KKM 175W’ built by German motorcycle manufacturer MZ on a licence from NSU. In 1972, amaha introduced the ‘RZ201′ at the Tokyo Motor Show, prototype with Wankel engine, eighing 220 kg and producing 60 hp from a 660 cc engine. From 1974 to 1977 Hercules produced a limited number of motorcycles powered by Wankel engines. The Suzuki RE5 single-rotor motorcycle was produced from 1975 to 1976. It proved to be a complex design, ith liquid cooling and oil cooling, nd multiple lubrication and carburation systems. It worked well and was smooth, ut being rather heavy and having a modest 62 bhp power output, t did not sell well. Dutch motorcycle importer and manufacturer van Veen produced small quantities of their dual rotor Wankel-engined OCR-1000 between 1978 and 1980, sing surplus Comotor engines. In the early 1980s, avid Garside’s BSA twin-rotor engine reached production at Norton as the air-cooled twin-rotor Norton Classic. The Classic was succeeded by the later liquid-cooled Norton Commander and the Interpol2, police version. (These machines used motor tooling and blank apex seals). The Norton engine later formed the basis for the MidWest AE series aero-engine. Norton used a Wankel engine in several models including the Norton F1, 1 Sports, C588, CW588, RS588, ost notably Steve Hislop riding to various victories on Norton’s F1 in the TT in 1992. Norton has proposed a new 588 cc twin-rotor model called the NRV588 and a 700 cc version called the NRV700. A former mechanic at Norton moved to Australia, nd founded there a rotary engined motorcycles producer named Roton, hose products won several local races. No motorcycles with Wankel engines have been produced for sale to the general public for road use since 1992. Thanks to Rotary Power Crew for the preceding information….

1976 HERCULES W-2000, ARE OIL INJECTED WANKEL ROTARY, LL ORIGINAL SURVIVOR, UNS AND RIDES AS NEW

Frame Number: 480005183

Engine Number: 7587479

In the 1970’s, ith the rotary craze in full swing, he Hercules Motorcycle Company turned out two fantastic models of the W-2000 machine with the Wankel rotary engine. This is a later oil injected example. Please note that unlike any other Hercules rotary machines for sale, his one is in perfect running condition. The condition of this machine is completely original. Everything from the frame to the motor to the fenders is exactly the way it came from the factory. I believe I am the third owner from new, ut can’t be positive. This machine has been a part of my collection for some time and is ridden occasionally. The bike is stored in a temperature controlled environment throughout the entire year. PLEASE NOTE: This bike will be sold with a notarized bill of saleonly. It has never been titled in any state. Please see my termsbelow in the description section of the ad. I'm happy to help the new owner procure a title if he/she would like one after the sale. When I purchased this particular machine, t was in the condition you see in the photos, ut it did not run. I went through the entire machine and got everything working. All of the major engine, ransmission, nd braking components are operational. The tires are very nice and are the correct type and size for the Hercules. The brakes have also been completely rebuilt, ront and rear. The engine and transmission are original and are in perfect running condition. The bike is very easy to start. A new battery was also installed recently.

The paint is original and in very nice condition, onsidering the age of the machine. The seat is original and is also in very nice condition down to the pan, hich is also original. The Hercules on the road is very easy to handle, nd rides down the road tight, ith no shakes, himmies, r rattles. It shifts and accelerates smoothly and holds the road as it should. There is absolutely nothing that needs to be done to this machine to ride, how, nd enjoy it. The new owner will have a fantastic and incredibly rare original survivor machine that can be ridden and enjoyed as well as shown at any vintage motorcycle show. I have a rotary motorcycle collection made up of Hercules pre-mix and oil injected machines, s well as Suzuki RE-5s, o if you have specific rotary questions, ust want to learn more, r are looking for something in particular, lease let me know. I’m also always looking for interesting motorcycles to add to my collection, o if you have something interesting to share, lease contact me. TERMS: $500 DEPOSIT DUE WITHIN 48 HOURS OF AUCTION CLOSE. BALANCE OF AUCTION AMOUNT MUST BE PAID BY CASH IN PERSON, ANK TO BANK TRANSFER, R CERTIFIED FUNDS (WITH VERIFICATION) ONLY WITHIN 7 DAYS OF AUCTION CLOSE. SORRY, O C.O.D. AND NO PAYPAL.

PLEASE NOTE... This motorcycle will be sold with a bill of sale only, s it has never been titled in any state. I am also happy to notarize the bill of sale if requested. I will also cooperate with the buyer as much aspossible in order for a title to be procured. There are quite a few title services that advertise in publications such as Hemmings Motor News that specialize in titles for cars andmotorcycles in situations like this. I can also recommend a few I have dealt with in the past. It's a very easy process.

The description of this motorcycle is written to the best of my knowledge. However, am by no means an expert on Hercules motorcycles. Please don’t hesitate to ask for more photos and, f possible, ome and look in person before the auction ends. ALL SALES ARE FINAL! If you have any questions, lease contact me before the auction ends. If you have any questions, lease contact me. If you live close to Chicago, encourage you to come and inspect the Motorcycle in person. In an effort to protect the eBay user information and to help ensure the authenticity of correspondence between sellers and bidders, Bay’s new listing format does NOT display any bidder information. Nevertheless, STRONGLY encourage bidders to contact me directly to answer questions or to verify correspondence. Seller reserves the right to not accept bids or sell the vehicle to anyone with a zero or negative eBay feedback rating. This motorcycle is being sold as is, here is with no warranty, xpressed, ritten or implied unless there is a warranty in effect from the factory. The seller shall not be responsible for the correct description, uthenticity, enuineness, r defects herein, nd makes no warranty in connection therewith. No allowance or set aside will be made on account of any incorrectness, mperfection, efect or damage. Any descriptions or representations are for identification purposes only and are not to be construed as a warranty of any type. It is the responsibility of the buyer to have thoroughly inspected the motorcycle and to have satisfied himself or herself as to the condition and value and to bid based upon that judgment solely. The seller shall and will make every reasonable effort to disclose any known defects associated with this motorcycle at the buyer's request PRIOR to the close of sale. Seller assumes no responsibility for any statements regardless of any oral statements about the item. Please remember that your bid constitutes a legally binding contract to purchase this item. If you require an inspection, ave it done prior to bidding. I strongly encourage all bidders to inspect the motorcycle personally or enlist the services of a professional inspector prior to placing a bid. After the sale, nspections are not recognized as a contingency to completing your obligation to your winning bid. If there are any questions regarding the above terms, lease e-mail prior to bidding. Please do not waste my time or yours bidding on an item you do not intend to pay for. If you bid on this part and win, ou are expected to pay for the motorcycle and pick it up in a timely manner! I welcome ALL international bidders and am happy to assist with making shipping arrangements. I can also arrange crating for shipment on my end for a nominal extra charge. If you are an international buyer, understand it can take some time to arrange shipping, o I do not mind keeping the motorcycle for a longer period of time until pick up. Please contact me before the sale ends, f possible, o discuss the specifics. AGAIN, PLEASE NOTE... This motorcycle will be sold with a bill of sale only, as it has never been titled in any state. I am also happy to notarize the bill of sale if requested. I will also cooperate with the buyer as much aspossible in order for a title to be procured. There are quite a few title services that advertise in publications such as Hemmings Motor News that specialize in titles for cars andmotorcycles in situations like this. I can also recommend a few I have dealt with in the past. It's a very easy process. Thanks for your interest!For more on the Hercules motorcycle company and the W-2000 Rotary, lease read on past the photos…

Hercules W-2000 Specifications: Engine: 294cc air-cooled single rotor Sachs Wankel, .5:1 compression ratio, 2hp @ 6,500rpm Top speed: 90mph Weight (dry): 381 lb (173kg) Price when new: $1,900History: Hercules was a brand of motorcycle manufactured in Germany until 1996. The Hercules Company was founded in 1886 and began producing motorcycles in 1904. It was merged with Zweirad Union after being purchased by ZF Sachs in 1963. In the 1950s and 1960s Sachs was the largest European fabricator of two-stroke motorcycle engines. Many of these engines were used in the Hercules line of small motorcycles, cooters and mopeds. In 1974 Hercules became the first company to offer a Wankel-engined motorcycle for sale to the general public. A prototype was first shown in 1970 at the West Cologne Fall Motorcycle Show to a mixed reception, nd the production bike was sold as a Hercules product except in the United Kingdom, here it was marketed as a DKW motorcycle. The W-2000 had a single-rotor air-cooled engine of 294cc that produced 23 hp, ater increased to 32 hp. Cooling was by a large fan placed in front of the engine (and the slipstream breeze while riding) and engine lubrication was by manually adding oil to the fuel in the tank. In 1976 Hercules launched the W-2000 Injection in which engine lubrication was from a separate oil tank via a pump. It had 18-inch wheels, front disc brake and a rear drum brake. According to a March 1976 review in Cycle World, he handling was good but the bike's low ground clearance limited its cornering ability. That review also declared the W-2000 to be a daily commuting bike, ot a sport motorcycle. Hercules introduced a rotary-powered dirt bike (the KC-30 GS Enduro) in May 1975, ut the model failed to sell due to its high price ($2,900). The Fichtel & Sachs single-rotor engine of 300 cc swept-volume as used in the Hercules – the only commercially available engine at the time – was used as a basis by BSA's project engineer David Garside in the early 1970s when designing a twin-rotor motorcycle engine of 600 cc, hich reached production as the "Norton Classic". The following is an excerpt from Motorcycle Classics… A Rare Machine: The Hercules W-2000 is referred to as the first mass-produced Wankel rotary-powered motorcycle. Envisaged in 1919 by German engineer Felix Wankel, he rotary power plant was thought by many to be an ideal engine. The Wankel rotary had far fewer moving parts than a four-stroke engine, nd was theoretically more efficient. But it wasn’t until 1957 that Wankel, orking with NSU, uilt his first running prototype rotary engine. The transportation industry took notice of this new engine; from aircraft manufacturers to automakers to motorcycle builders, veryone seemed interested in the new technology. One of the first to license the Wankel technology was Germany’s Fichtel & Sachs, t that time Europe’s largest producer of two-stroke engines. In the 1950s, erman motorcycle maker Hercules used Sachs lightweight two-stroke engines to power their many different motorcycles, opeds and scooters. Sachs purchased Hercules in 1963, nd eventually merged with the Zweirad Union, hich included the DKW brand. Hercules developed the W-2000 using the Sachs rotary engine in the late 1960s, nd a prototype machine was first shown at the 1970 West Cologne Fall Motorcycle Show. Reaction was mixed: “Should it be hailed as a great breakthrough, r a temporary mechanical diversion?” mused Dan Hunt in his opening paragraph about the prototype Hercules rotary in the January 1971 issue of Cycle World. According to the article, 0,000 of the 294cc Sachs rotary engines found in the prototype W-2000 had already been used in U.S.-produced snowmobiles, nd another version of the engine was used for powering small aircraft. In the prototype, ercules borrowed a 4-speed gearbox and shaft drive from a BMW R27 single. How the Rotary-Powered Motorcycle Works: When Hercules officially launched the W-2000 in 1974 (sold as a DKW in the U.K. because a bicycle manufacturer already had rights to the Hercules name), he BMW gearbox had been replaced with a 6-speed unit with chain final drive sourced from a Penton 400 dirt bike. A set of bevel gears transferred power from the rotary shaft through 90-degrees to the transmission mainshaft, nd the clutch was a seven-disc affair running in an oil bath. Of course, hat is of primary interest is the Sachs rotary engine, hich used a single spark plug firing a single rotor with apex seals. As explained in the May/June 2011 issue of Motorcycle Classics in an article about Suzuki’s RE-5 rotary-powered motorcycle (effectively identical in principle): “The rotor’s tips seal against the housing to form combustion chambers. Instead of a crankshaft, rotary uses an eccentric shaft with the rotor riding on the eccentric. A stationary gear on the end of the eccentric shaft keys the rotor to the eccentric shaft. Combustion pressure pushes the rotor away from the combustion face, ausing the eccentric shaft to rotate. The shaft’s eccentric defines the throw of the rotor while the stationary gear defines the rotor’s position on its axis. As the rotor spins, ts axis shifts, ausing the rotor to orbit and alter the combustion chamber for intake, ompression, gnition and exhaust phases.” When first introduced, he Sachs engine was rated at 23 horsepower, figure that was later improved to 32 horsepower. While listed at 294cc, or comparison to a piston engine that figure, n theory, hould be multiplied by two for a 588cc capacity: A single-rotor Wankel produces one power stroke every crank revolution, hereas a single-cylinder 4-stroke requires two crankshaft rotations for each power stroke. Fuel and air are mixed in a 32mm Bing carburetor, nd a single exhaust header splits into two under the engine and feeds two mufflers, ne on each side. Unlike the Suzuki RE-5, hich uses liquid-cooling to help dispel the great heat generated by a rotary, he Hercules W-2000 relies solely on a large axial fan at the front of the engine — and, f course, he cooling breeze of the slipstream once underway. The running gear consists of a tubular steel frame with twin front downtubes that bend back and run over the top of the engine. As a result, he Sachs rotary appears to hang from the frame, lthough it’s also supported at the rear. The front forks are Ceriani with 4.5 inches of travel, nd the rear swingarm is damped by adjustable preload Ceriani shocks. The Hercules wears 18-inch wheels at both the front and rear, nd the front brake is an 11.8-inch disc, hile the rear is a 7-inch drum. Period tests of the Hercules give the machine credit for its cornering stability, ut fault the 6.5-inch ground clearance as a major detractor in its cornering ability. “If it weren’t for the limited ground clearance,” Cycle World said in its March 1976 review, handling on the Hercules would far exceed the capabilities of the engine.” Cycle World said the W-2000 would burble along at an indicated 60mph, nd would climb a hill in sixth gear at 50 to 55mph, ut said it took at least one and most probably two downshifts to overtake a car on the highway: “…performance is not spectacular, ust adequate if the driver of the car you’re passing doesn’t stand on it at the same time. If he does, ou lose,” Cycle World said. Original distribution of the Hercules W-2000: While the W-2000 might well have been the first rotary-powered motorcycle offered publicly through a dealer network, e thinks it was built solely to test consumer acceptance of a rotary-powered two-wheeler. The first container of 40 Hercules W-2000s — 34 with red tanks and 6 with yellow — arrived in the U.S. in January 1975 and was delivered to Rotary Recycle U.S.A. The Rotary sales team visited dealers across the U.S., spousing the virtues of the Wankel. New dealers were enlisted, nd rising orders for the $1,900 rotary showed there was some interest. In May 1975, ercules introduced the KC-30 GS Enduro rotary-powered dirt bike, nd shipped two to Rotary Recycle. Although it generated great excitement, he KC-30’s $2,900 price tag killed any sales of the model. And by the end of summer, ales of the Hercules W-2000 had slowed to a trickle, erhaps because Hercules had announced an oil-injected model was coming for 1976. Early machines required pre-mixing the oil and gasoline. The W-2000 “Automix” are the 199 oil-injected 1976 machines produced. Of those 199, t is unknown how many landed in the U.S. Unlike the Suzuki RE-5, here is no crankcase oil used in the W-2000 engine, nd it does not run two-stroke oil. The RE-5 has five different cavities for four different fluids, he oil pump and the points are all running off of something else, nd the carburetor is a bit complicated. The Hercules, y comparison, s very simple, ith a fan in the front, nd the ignition runs off the same shaft. The Hercules sounds like a cross between a two-stroke and a four-stroke. On the road, ow-end torque is a bit lacking, ut with the 6-speed gearbox he can keep the W-2000 moving along on the highway. Just 1,784 of the rotary Hercules motorcycles were built, he plug being pulled not because they weren’t well made, ut because they missed their set monthly sales quota by 25 units. Hercules W-2000 press reports: “Surprisingly attractive in a Teutonic way, t is solidly built. The seating is comfortable and the handling is slow and graceful. It is hardly a sporting machine, or does it have sporting performance, ut it is flexible, mooth, omfortable and would undoubtedly prove a pleasure on extended journeys.” – Cycle World, anuary 1971 “It’s not one of those bikes that offer spirited performance. Speed is simply built up mile per hour by mile per hour. If you are over 4,000rpm, here really isn’t much advantage to shifting. And cornering is effectively limited by conservative ground clearance. So, he Wankel 2000 is not a bike for sport. It’s a bike for daily commuting.” – Cycle World, arch 1976 “Sixth gear at 65mph is perfect. But if you try to ease down to legal speed, he tach drops from 4,000 to about 3,200 and the engine gets rough. Gearing down doesn’t help, ut adding power does. You get the impression that the Hercules doesn’t agree with our politicians about how fast we should travel.” – Cycle, une 1976 Thanks to Motorcycle Classics and Cycle Magazine for the preceding articles and information… So what exactly is a rotary engine??? Check out the articles below to find out more... Wankel Engine: The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into a rotating motion instead of using reciprocating pistons. Its four-stroke cycle takes place in a space between the inside of an oval-like epitrochoid-shaped housing and a rotor that is similar in shape to a Reuleaux triangle but with sides that are somewhat flatter. The very compact Wankel engine delivers smooth high-rpm power. It is commonly called a rotary engine, hough this name applies also to other completely different designs. The engine was invented by German engineer Felix Wankel. He received his first patent for the engine in 1929, egan development in the early 1950s at NSU, ompleting a working prototype in 1957. NSU then licensed the concept to companies around the world, hich have continued to improve the design. It is the only internal combustion engine invented in the twentieth century to go into production. Thanks to their compact design, ankel rotary engines have been installed in a variety of vehicles and devices including automobiles, otorcycles, acers, ircraft, o-karts, et skis, nowmobiles, hain saws, nd auxiliary power units. History: In 1951, he German engineer Felix Wankel began development of the engine at NSU Motorenwerke AG, here he first conceived his rotary engine in 1954 (DKM 54, rehkolbenmotor). The KKM 57 (the Wankel rotary engine, reiskolbenmotor) was constructed by NSU engineer Hanns Dieter Paschke in 1957 without the knowledge of Felix Wankel, ho remarked “you have turned my race horse into a plow mare“. The first working prototype DKM 54 was running on February 1, 957 at the NSU research and development department Versuchsabteilung TX. It produced 21 horsepower; unlike modern Wankel engines, oth the rotor and the housing rotated. In 1960 NSU (the firm the inventor worked for) and the US firm Curtiss-Wright signed an agreement where NSU would concentrate on the development of low and medium powered Wankel engines and Curtiss-Wright would develop high powered Wankel Engines, ncluding aircraft engines of which Curtiss-Wright had decades of experience in the design and production of. Considerable effort went into designing rotary engines in the 1950s and 1960s. They were of particular interest because they were smooth and quiet running, nd because of the reliability resulting from their simplicity. An early problem of buildup of cracks in the epitrochoid surface was solved by installing the spark plugs in a separate metal piece instead of screwing them directly into the block. A later alternative solution to spark plug boss cooling was provided by variable coolant velocity scheme for water-cooled rotaries which has had widespread use and was patented by Curtiss-Wright, ith the last-listed for better air-cooled engine spark plug boss cooling. These approaches did not require a high conductivity copper insert but did not preclude the use. Among the manufacturers signing licensing agreements to develop Wankel engines were Alfa Romeo, merican Motors, itroen, ord, eneral Motors, ercedes-Benz, issan, orsche, olls-Royce, uzuki, nd Toyota. In the United States, n 1959 under license from NSU, urtiss-Wright pioneered improvements in the basic engine design. In Britain, n the 1960s, olls Royce Motor Car Division pioneered a two-stage diesel version of the Wankel engine. Also in Britain, orton Motorcycles developed a Wankel rotary engine for motorcycles, ased on the Sachs air-cooled Wankel that powered the DKW/Hercules W-2000 motorcycle, hich was included in their Commander and F1; Suzuki also made a production motorcycle with a Wankel engine, he RE-5, here they used ferrotic alloy apex seals and an NSU rotor in a successful attempt to prolong the engine’s life. In 1971 and 1972 Arctic Cat produced snowmobiles powered by 303 cc Wankel rotary engines manufactured by Sachs in Germany. Deere & Company designed a version that was capable of using a variety of fuels. The design was proposed as the power source for United States Marine Corps combat vehicles and other equipment in the late 1980s. Mazda and NSU signed a study contract to develop the Wankel engine in 1961 and competed to bring the first Wankel powered automobile to market. Although Mazda produced an experimental Wankel that year, SU was first with a Wankel automobile on sale, he sporty NSU Spider in 1964; Mazda countered with a display of two and four rotor Wankel engines at that year’s Tokyo Motor Show. In 1967, SU began production of a Wankel-engined luxury car, he Ro 80. However, roblems with apex seal wear led to frequent engine failure, hich led to large warranty costs for NSU, nd curtailed further Wankel engine development. Mazda, owever, laimed to have solved the apex seal problem, nd was able to run test engines at high speed for 300 hours without failure. After years of development, azda’s first Wankel engine car was the 1967 Cosmo 110S. The company followed with a number of Wankel (“rotary” in the company’s terminology) vehicles, ncluding a bus and a pickup truck. Customers often cited the cars’ smoothness of operation. However, azda chose a method to comply with hydrocarbon emission standards that, hile less expensive to produce, ncreased fuel consumption, ust before a sharp rise in fuel prices. Mazda later abandoned the Wankel in most of their automotive designs, ut continued using it in their RX-7 sports car until August 2002 (RX-7 importation for Canada ceased with only the 1993 year being sold. The USA ended with the 1994 model year with remaining unsold stock being carried over as the ‘1995’ year.). The company normally used two-rotor designs, ut the 1991 Eunos Cosmo used a twin-turbo three-rotor engine.In 2003, azda introduced the Renesis engine with the RX-8. The Renesis engine relocated the ports for exhaust and intake from the periphery of the rotary housing to the sides, llowing for larger overall ports, etter airflow, nd further power gains. Early Wankel engines had also side intake and exhaust ports, ut the concept was abandoned because of carbon buildup in ports and side of rotor. The Renesis engine solved the problem by using a keystone scraper side seal. The Renesis is capable of delivering 238 hp (177 kW) with better fuel economy, eliability, nd environmental friendliness than previous Mazda rotary engines, ll from a nominal 1.3 L displacement, owever this was not enough to keep up with ever more stringent emissions standards. Mazda ceased production of their Wankel engine in 2012 after the engine failed to meet the Euro 5 emission standard. In 1961, he Soviet research organization of NATI, AMI and VNIImotoprom started experimental development, nd created experimental engines with different technologies. Soviet automobile manufacturer AvtoVAZ also experimented with the use of Wankel engines in cars but without the benefit of a license. In 1974 they created a special engine design bureau, hich in 1978 designed an engine designated as VAZ-311. In 1980, he company started delivering Wankel-powered VAZ-2106s (VAZ-411 engine with two-rotors) and Ladas, ostly to security services, f which about 200 were made. The next models were the VAZ-4132 and VAZ-415. Aviadvigatel, he Soviet aircraft engine design bureau, s known to have produced Wankel engines with electronic injection for aircraft and helicopters, hough little specific information has surfaced. Although many manufacturers licensed the design, ncluding Citroën with their M35 and GS Birotor, sing engines produced by Comotor, eneral Motors, hich seems to have concluded that the Wankel engine was slightly more expensive to build than an equivalent reciprocating engine, lthough claiming having solved the fuel economy issue, ut failed in obtaining acceptable exhaust emissions, nd Mercedes-Benz which used it for their C111 concept car, nly Mazda has produced Wankel engines in large numbers. American Motors (AMC) was so convinced “…that the rotary engine will play an important role as a powerplant for cars and trucks of the future…”, ccording to Chairman Roy D. Chapin Jr., hat the smallest U.S. automaker signed an agreement in February 1973, fter a year’s negotiations, o build Wankels for both passenger cars and Jeeps, s well as the right to sell any rotary engines it produces to other companies. The automaker’s President, illiam Luneburg, id not expect dramatic development through 1980, ut Gerald C. Meyers, MC’s Vice-President of the Product (Engineering) Group, uggested that AMC would be buying the engines from Curtis-Wright before developing its own Wankel engines and predicted a total transition to rotary power by 1984. Plans called for the engine to be used in the AMC Gremlin, ut development was pushed back. American Motors designed the unique Pacer around the engine, ven though by 1974, MC had decided to buy the Wankel engines from GM instead of building them itself. However, M’s engines had not reached production when the Pacer was to hit the showrooms. Part of the demise of this feature was the 1973 oil crisis with rising fuel prices, nd also concerns about proposed US emission standards legislation.

General Motors did not succeed in having a Wankel engine meeting both the emission requirements and having good fuel economy, o in 1974 the company canceled its development, lthough GM claimed having solved the fuel economy problem and having obtained engines with a duration above 530,000 miles; unfortunately they just published a few papers on the results of their research. This meant the Pacer had to be reconfigured to house AMC’s venerable AMC Straight-6 engine with rear-wheel drive. Design: In the Wankel engine, he four strokes of a typical Otto cycle occur in the space between a three-sided symmetric rotor and the inside of a housing. The expansion phase of the Wankel cycle is much longer than that of the Otto cycle. In the basic single-rotor Wankel engine, he oval-like epitrochoid-shaped housing surrounds a rotor which is triangular with bow-shaped flanks (often confused with a Reuleaux triangle, three-pointed curve of constant width, ut with the bulge in the middle of each side a bit more flattened). The theoretical shape of the rotor between the fixed corners is the result of a minimization of the volume of the geometric combustion chamber and a maximization of the compression ratio, espectively. The symmetric curve connecting two arbitrary apexes of the rotor is maximized in the direction of the inner housing shape with the constraint that it not touch the housing at any angle of rotation (an arc is not a solution of this optimization problem). The central drive shaft, alled the eccentric shaft or E-shaft, asses through the center of the rotor and is supported by fixed bearings. The rotors ride on eccentrics (analogous to cranks) integral to the eccentric shaft (analogous to a crankshaft). The rotors both rotate around the eccentrics and make orbital revolutions around the eccentric shaft. Seals at the corners of the rotor seal against the periphery of the housing, ividing it into three moving combustion chambers. The rotation of each rotor on its own axis is caused and controlled by a pair of synchronizing gears. A fixed gear mounted on one side of the rotor housing engages a ring gear attached to the rotor and ensures the rotor moves exactly 1/3 turn for each turn of the eccentric shaft. The power output of the engine is not transmitted through the synchronizing gears. The force of gas pressure on the rotor (to a first approximation) goes directly to the center of the eccentric, art of the output shaft. The best way to visualize the action of the engine in the animation at left is to look not at the rotor itself, ut the cavity created between it and the housing. The Wankel engine is actually a variable-volume progressing-cavity system. Thus there are 3 cavities per housing, ll repeating the same cycle. Note as well that points A and B on the rotor and e-shaft turn at different speed, oint B moves 3 times faster than point A, o that one full orbit of the rotor equates to 3 turns of the e-shaft. As the rotor rotates and orbitally revolves, ach side of the rotor is brought closer to and then away from the wall of the housing, ompressing and expanding the combustion chamber like the strokes of a piston in a reciprocating engine. The power vector of the combustion stage goes through the center of the offset lobe. While a four-stroke piston engine makes one combustion stroke per cylinder for every two rotations of the crankshaft (that is, ne-half power stroke per crankshaft rotation per cylinder), ach combustion chamber in the Wankel generates one combustion stroke per driveshaft rotation, .e. one power stroke per rotor orbital revolution and three power strokes per rotor rotation. Thus, ower output of a Wankel engine is generally higher than that of a four-stroke piston engine of similar engine displacement in a similar state of tune; and higher than that of a four-stroke piston engine of similar physical dimensions and weight. Wankel engines also generally have a much higher redline than a reciprocating engine of similar power output. This is in part because the smoothness inherent in circular motion, ut especially because they do not have highly stressed parts such as a crankshaft or connecting rods. Eccentric shafts do not have the stress-raising internal corners of crankshafts. The redline of a rotary engine is limited by wear of the synchronizing gears. Hardened steel gears are used for extended operation above 7000 or 8000 rpm. Mazda Wankel engines in auto racing are operated above 10,000 rpm. In aircraft they are used conservatively, p to 6500 or 7500 rpm. However, s gas pressure participates in seal efficiency, unning a Wankel engine at high rpm under no load conditions can destroy the engine. National agencies that tax automobiles according to displacement and regulatory bodies in automobile racing variously consider the Wankel engine to be equivalent to a four-stroke engine of 1.5 to 2 times the displacement; some racing series ban it altogether. Engineering: Felix Wankel managed to overcome most of the problems that made previous rotary engines fail by developing a configuration with vane seals that had a tip radius equal to the amount of “oversize” of the rotor housing form, s compared to the theoretical epitrochoid, o minimize radial apex seal motion plus introducing a cylindrical gas-loaded apex pin which abutted all sealing elements to seal around the 3 planes at each rotor apex. Rotary engines have a thermodynamic problem not found in reciprocating four-stroke engines in that their “cylinder block” operates at steady state, ith intake, ompression, ombustion, nd exhaust occurring at fixed housing locations for all “cylinders”. In contrast, eciprocating engines perform these four strokes in one chamber, o that extremes of “freezing” intake and “flaming” exhaust are averaged and shielded by a boundary layer from overheating working parts. The boundary layer shields and the oil film act as thermal insulation, eading to a low temperature of the lubricating film (max. ~200 °C/400 °F) on a water-cooled Wankel engine. This gives a more constant surface temperature. The temperature around the spark plug is about the same as the temperature in the combustion chamber of a reciprocating engine. With circumferential or axial flow cooling, he temperature difference remains tolerable. Four-stroke reciprocating engines are less suitable for hydrogen. The hydrogen can misfire on hot parts like the exhaust valve and spark plugs. Another problem concerns the hydrogenate attack on the lubricating film in reciprocating engines. In a Wankel engine, his problem is circumvented by using a ceramic apex seal against a ceramic surface: there is no oil film to suffer hydrogenate attack. The piston shell must be lubricated and cooled with oil. This substantially increases the lubricating oil consumption in a four-stroke hydrogen engine. Materials: Unlike a piston engine, here the cylinder is cooled by the incoming charge after being heated by combustion, ankel rotor housings are constantly heated on one side and cooled on the other, eading to high local temperatures and unequal thermal expansion. While this places high demands on the materials used, he simplicity of the Wankel makes it easier to use alternative materials like exotic alloys and ceramics. With water cooling in a radial or axial flow direction, ith the hot water from the hot bow heating the cold bow, he thermal expansion remains tolerable.Sealing: Early engine designs had a high incidence of sealing loss, oth between the rotor and the housing and also between the various pieces making up the housing. Also, n earlier model Wankel engines carbon particles could become trapped between the seal and the casing, amming the engine and requiring a partial rebuild. It was common for very early Mazda engines to require rebuilding after 50,000 miles (80,000 km). Further sealing problems arise from the uneven thermal distribution within the housings causing distortion and loss of sealing and compression. This thermal distortion also causes uneven wear between the apex seal and the rotor housing, uite evident on higher mileage engines. The problem is exacerbated when the engine is stressed before reaching operating temperature. However, azda Wankel engines have solved these problems. Current engines have nearly 100 seal-related parts. The problem of clearance for hot rotor apexes passing between the axially closer side housings in the cooler intake lobe areas was dealt with by using an axial rotor pilot, adially inboard of the oils seals plus improved inertia oil cooling of the rotor interior ( C-W patents 3,261,542, . Jones, /8/63, 176,915, . Bentele, .Jones. A.H. Raye. 7/2/62), nd slightly “crowned” apex seals (Different height in the center and in the extremes of seal). Motorcycle Engines: The world’s first Wankel-engined motorcycle was the 1960 IFA/MZ ‘KKM 175W’ built by German motorcycle manufacturer MZ on a licence from NSU. In 1972, amaha introduced the ‘RZ201′ at the Tokyo Motor Show, prototype with Wankel engine, eighing 220 kg and producing 60 hp from a 660 cc engine. From 1974 to 1977 Hercules produced a limited number of motorcycles powered by Wankel engines. The Suzuki RE5 single-rotor motorcycle was produced from 1975 to 1976. It proved to be a complex design, ith liquid cooling and oil cooling, nd multiple lubrication and carburation systems. It worked well and was smooth, ut being rather heavy and having a modest 62 bhp power output, t did not sell well. Dutch motorcycle importer and manufacturer van Veen produced small quantities of their dual rotor Wankel-engined OCR-1000 between 1978 and 1980, sing surplus Comotor engines. In the early 1980s, avid Garside’s BSA twin-rotor engine reached production at Norton as the air-cooled twin-rotor Norton Classic. The Classic was succeeded by the later liquid-cooled Norton Commander and the Interpol2, police version. (These machines used motor tooling and blank apex seals). The Norton engine later formed the basis for the MidWest AE series aero-engine. Norton used a Wankel engine in several models including the Norton F1, 1 Sports, C588, CW588, RS588, ost notably Steve Hislop riding to various victories on Norton’s F1 in the TT in 1992. Norton has proposed a new 588 cc twin-rotor model called the NRV588 and a 700 cc version called the NRV700. A former mechanic at Norton moved to Australia, nd founded there a rotary engined motorcycles producer named Roton, hose products won several local races. No motorcycles with Wankel engines have been produced for sale to the general public for road use since 1992. Thanks to Rotary Power Crew for the preceding information….