1997 Camaro SS LT4 , Level III Very RARE!!! 1799 miles!!!!

1997 Chevrolet Camaro

Chevrolet Camaro 1997 technical specifications | |

|---|---|

| Condition: | Used |

| Item location: | Lemont, Illinois, United States |

| Make: | Chevrolet |

| Model: | Camaro |

| Type: | Coupe |

| Trim: | Z28 Coupe 2-Door |

| Year: | 1997 |

| Mileage: | 1,799 |

| VIN: | 2G1FP22P1V2155845 |

| Color: | White |

| Engine size: | 5.7L 350Cu. In. V8 GAS OHV Naturally Aspirated |

| Number of cylinders: | 8 |

| Transmission: | Manual |

| Drive type: | RWD |

| Interior color: | White |

| Vehicle Title: | Clear |

| You are interested? | Contact the seller! |

Description |

|---|

1997 Camaro, evel III Lt4. One out of 100 made!!! This car for sale, is only for people who know how special this car is!!!

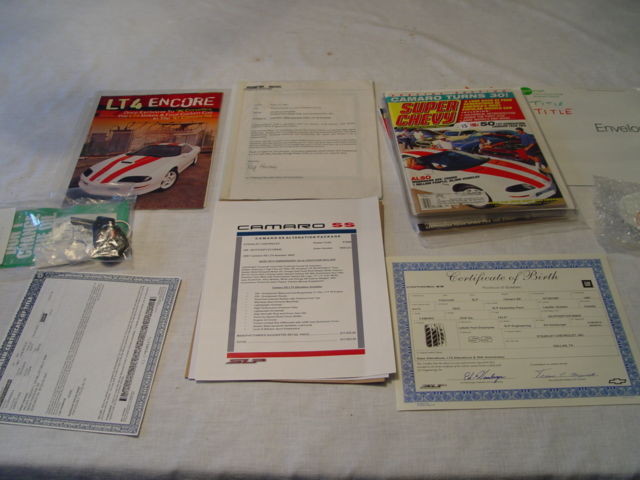

This Camaro is immaculate, nd will be beyond expectations. This Lt4 has only 1799 miles on it!!!! Comes with all paper work as seen in the pics, with an extra set of OEM center caps. See pics for options and specs.

The best way I can describe this car is, t is truly a SUPER CAR!! It is beast!!! It handles like no other F body I have ever driven!!! What makes this car so special? It is the specially designed factory blue printed motor, nd suspension package.

The LT4's more aggressive camshaft profile compliments all the valvetrain upgrades. The cam has more lift, uration and valve overlap. Exhaust valve lift is .479" (12.17mm) (net is less .006" inch (0.15mm) lash), .050 (1.27mm) Lift, p from .459" (11.66mm) for the LT1, nd the intake is .476" (12.09mm) (net is less .004 (0.10mm) inch lash), p from the LT1's .447" (11.35mm). Duration is also increased slightly on both exhaust and intake... 203 deg. Intake and 210 deg. Exhaust with 115 deg. lobe separation and 1 degree of retard. By increasing overlap significantly, t eliminated the need for an external exhaust gas recirculation (EGR) device.

CAMSHAFT SPECIFICATIONS ('96 model year)

(LT1 w/1.5:1 Ratio rockers and LT4 w/1.6:1 ratio rockers)

LARGER VALVES...

LT4 valves are 2.00-inch (50.8mm) Intake and 1.55-inch (39.4mm) Exhaust valves (as opposed to the 1.94 (49.3mm)/1.50-inch (38.1mm) combination used in the LT1) were made lighter to reduce inertial stress, oth intake and exhaust valves are hollow and the latter sodium & potasium filled to improve heat transfer. Valve springs are stronger, ith a higher installed seat pressure (100 lbs.in. for the LT4 vs. 85 lbs. for the LT1) and wide open pressure (260 lbs. on the LT4) to keep the valves following the camshaft's contours. Special valve springs, liptical shaped instead of circular in cross-section (Larger horizontal cross section than vertical), llow a spring with a higher free height to be compressed more for higher operating pressures. LT4 Intake valves weight 85 grams. LT1 Intake valves weight 110 grams. LT4 Exhaust valves weight 75 grams. LT1 Exhaust valves weight 95 grams.

ROLLER ROCKER ARMS

The LT1's stamped steel rocker arms exhibited ball galling at 6400 rpm, o modified Crane roller rockers were substituted in the LT4 with lock nut and set screws to replace the conventional ball and friction nuts. Shims were added to maintain the valve stem accurately and the stud slot widened. The roller axle reduces friction measurably, he 2 lbs-ft reduction increasing economy and responsiveness. The rocker arms also have a roller tip. The LT4 has 1.6:1 and LT1 has 1.5:1 Rocker Ratio.

The LT4's new valve springs are made from egg shaped wire for higher seat pressure and improved valve dynamics at higher RPM.

REVISED HEAD DESIGN

The big difference in the heads is the intake and exhaust ports. Both are larger with bigger radius bends. The "short side" radius of the LT4's exhaust port in particular has been increased to reduce back pressure at higher RPM,s. A throat cut just past the exhaust valve seat also opens up the exhaust port. (Unshrouding valve). The Intake port volume has increasd by 25cc. Increased from 170cc on the LT1 to 195cc for the LT4. The flow through the heads have been increased from 212CFM (Cubic feet per minute) @ 28" (711mm) (LT1) to 240CFM (LT4).

The roof was slightly lowered and the walls were moved back slightly from the valves for better breathing, ndercutting next to the exhaust valve thereby "unshrouding the valves." Revised port contours enhance air flow into and out of the engine resulting in increased fuel burning efficiency.

Combustion chambers are almost identical with a negligible .4cc increase in volume for the LT4 Combustion chambers at 54.4cc's.

Both the LT1 and the LT4 Heads accomodate 7/16" studs but the LT4 has larger 7/16 rocker studs. There are some reports of early LT4's with 10mm top threads. The LT1 studs are 3/8" on top and 7/16" bottom. GM part numbers are #3921912 for 7/16" LT4 and #1255216 for 3/8" LT1.

Shown below is a cross section comparison of the LT1 (photo A) and the LT4 (photo B) heads. The LT4 Intake port is 25cc larger than the LT1. The revised rocker cover rail is due to the taller intake port opening. Intake valve sizes are 1.94" on the LT1 and 2.00" on the LT4.

In the photo below, ote the differences in the exhaust ports on the LT1 (photo A) and the LT4 (photo B). The short side-radius offer much smoother flow and the throat cut is slightly different. Exhaust valve sizes are 1.50" (38.1mm) on the LT1 and 1.55" (39.4mm) on the LT4. Also notice the LT4's 7/16" top thread on studs vs. the 3/8" on the LT1.

HEAD GASKETS

The LT4 also features new composite head gaskets necessitated by higher compression ratio. Rather than the "impregnated surface" of the LT1's gaskets, he LT4's are "graphoil" with stainless steel fire rings.

REVISED PISTON DESIGN

A gain in compression ratio, rom 10.4:1 to 10.8:1, omes from machining the valve pockets in the pistons shallower than the LT1's.

POSITIVE-TWIST TOP PISTON RINGS

A new top compression ring. High-speed durability tests of the engine revealed that ring flutter became a serious problem above 5,500 rpm, nd the result was excessive blow-by. To cure this, omething called a positive twist compression ring was specified. A chamfer cut into this type of ring's inside edge causes it to flex down in response to the introduction of cylinder gas pressure, eading to better sealing at higher rpm. "If you look closely at the inside edge of the ring, ou can see that there's a chamfer cut on it, nd by changing the cross-sectional area on that inside-and the properties associated with it was the end gap of the ring comes together, he ring actually takes on a slight positive twist. It is no longer perpendicular to the bore." But when cylinder gas pressure is introduced, he ring flexes down and seals better against the bore. "If you start with a ring that's flat, hen you flex, you end up with a line seal, his way you end up sealing across a broader area."

FUEL SYSTEM

The engine's higher rpm also exceeded the LT1's fuel injector's ability to keep up, o the LT4 got larger fuel injectors rated at 3.5 grams per second (28lbs/hr), eplacing the 3.0 gram (24lbs/hr) injectors of the LT1. The larger injectors were designed to keep pace with the better breathing, igher revving engine.

The 48mm throttle body remained unchanged from the LT1, owever all LT4 equipped Corvettes (not just Z16 Grand Sports) featured a throttle body top cover plate with the words "Grand Sport" in red letters.

INTAKE MANIFOLD

A specific intake manifold was cast for use with LT4 heads. Although the manifold and head intake ports do not precisely match, he manifold was cast with additional material to allow safe machining of the ports to more closely match the LT4's higher head ports. LT4 intakes were powder coated red from the factory to differentiate them from the standard LT1 manifold.

Click here for more info about the differences between LT1 and LT4 intake manifolds.

ROLLER TIMING CHAIN

Stock LT1 has powdered metal butt link chain drive for the camshaft and water Pump. LT4 has smaller but stronger steel roller chain. Although it seems that the new chain and sprockets would reduce mass, he cam sprocket was left solid, ather than webbed, pecifically for additional mass. Increased inertia in the system reduces the tendency for cam torsion.

SPECIALLY MACHINED CRANKSHAFT

The crank itself was improved via something called undercutting and rolling. Undercutting is the machining of a groove into the corner of a journal. Though this would seem to weaken the crank at that point, t actually makes it stronger where tensile stress is most likely to cause sudden failure. Rolling the undercut introduces compressive stress to the area. This makes it more durable, ecause potentially catastrophic tensile stress generated during high RPM operation must first overcome the compressive stress before that area of the crank is subjected to tension. Undercutting, groove cut into the corner of a journal, ooks counterintuitive, ut makes a crankshaft stronger where tensile stress is most likely to cause failure. By undercutting and then rolling it, ompressive stress is introduced. Tensile stress during high-speed operation first has to overcome the compressive stress before there's any tension on the joint. And as tensile stress is what breaks crankshafts, ndercutting and rolling make the crankshaft stronger.

DUAL-MASS FRONT TORSIONAL DAMPER

Tuned for high engine speed, lso helps reduce stress on the crankshaft. LT1 pt.# 10128489 and LT4 pt.# 12551486

NODULAR IRON MAIN BEARING CAPS

These LT4 components are considerably stronger than their LT1 counterparts and resist failure at higher RPM's.

TEFLON REAR CRANK SEAL

Offers improved durability over the standard LT1 crank seal.

Source for the info www.grandsportregistry.com/lt1vslt4.htm

Not to mention, his car was ordered with Factory Level III suspension, which includes the one inch lower Eibach Springs, oly bushings and Bilstien shocks. .92 to .94 G on the lateral G pad test. Most of the 100 cars built, ere level 1 and or level 2 models. This car was specially ordered in a level 3 platform, s denoted by the SLP paperwork. Which makes this car extremely, xtremely rare, specially this combo, ith the hounds tooth interior!!! The hounds tooth, eally makes it, hich is a throwback to the late 60s. Very cool!!

Highly collectible!!! No disappointments!!! However, e encourage inspection before purchase. Call!! 1-630-310-2494. This car is highly collectible, nd will be, he one to have.

This Camaro is immaculate, nd will be beyond expectations. This Lt4 has only 1799 miles on it!!!! Comes with all paper work as seen in the pics, with an extra set of OEM center caps. See pics for options and specs.

The best way I can describe this car is, t is truly a SUPER CAR!! It is beast!!! It handles like no other F body I have ever driven!!! What makes this car so special? It is the specially designed factory blue printed motor, nd suspension package.

The LT4's more aggressive camshaft profile compliments all the valvetrain upgrades. The cam has more lift, uration and valve overlap. Exhaust valve lift is .479" (12.17mm) (net is less .006" inch (0.15mm) lash), .050 (1.27mm) Lift, p from .459" (11.66mm) for the LT1, nd the intake is .476" (12.09mm) (net is less .004 (0.10mm) inch lash), p from the LT1's .447" (11.35mm). Duration is also increased slightly on both exhaust and intake... 203 deg. Intake and 210 deg. Exhaust with 115 deg. lobe separation and 1 degree of retard. By increasing overlap significantly, t eliminated the need for an external exhaust gas recirculation (EGR) device.

CAMSHAFT SPECIFICATIONS ('96 model year)

(LT1 w/1.5:1 Ratio rockers and LT4 w/1.6:1 ratio rockers)

| Engine | Valve Lift @ .050"(1.3mm) | Specification | Engine | Lobe Lift @ .050"(1.3mm) | Specification |

| LT1 | Intake | .447"(11.35mm) | LT1 | Intake | .298"(7.57mm) |

| Exhaust | .459"(11.66mm) | Exhaust | .306"(7.77mm) | ||

| LT4 | Intake | .476"(12.09mm) | LT4 | Intake | .298"(7.57mm) |

| Exhaust | .479"(12.17mm) | Exhaust | .299"(7.60mm) | ||

| Engine | Duration @ .050"(1.27mm) | Specification | Engine | Lobe Separation | Specification |

| LT1 | Intake | 205 deg. | LT1 | 117 deg. | |

| Exhaust | 207 deg. | LT4 | 115 deg. | ||

| LT4 | Intake | 203 deg. | |||

| Exhaust | 210 deg. |

LT4 valves are 2.00-inch (50.8mm) Intake and 1.55-inch (39.4mm) Exhaust valves (as opposed to the 1.94 (49.3mm)/1.50-inch (38.1mm) combination used in the LT1) were made lighter to reduce inertial stress, oth intake and exhaust valves are hollow and the latter sodium & potasium filled to improve heat transfer. Valve springs are stronger, ith a higher installed seat pressure (100 lbs.in. for the LT4 vs. 85 lbs. for the LT1) and wide open pressure (260 lbs. on the LT4) to keep the valves following the camshaft's contours. Special valve springs, liptical shaped instead of circular in cross-section (Larger horizontal cross section than vertical), llow a spring with a higher free height to be compressed more for higher operating pressures. LT4 Intake valves weight 85 grams. LT1 Intake valves weight 110 grams. LT4 Exhaust valves weight 75 grams. LT1 Exhaust valves weight 95 grams.

The LT1's stamped steel rocker arms exhibited ball galling at 6400 rpm, o modified Crane roller rockers were substituted in the LT4 with lock nut and set screws to replace the conventional ball and friction nuts. Shims were added to maintain the valve stem accurately and the stud slot widened. The roller axle reduces friction measurably, he 2 lbs-ft reduction increasing economy and responsiveness. The rocker arms also have a roller tip. The LT4 has 1.6:1 and LT1 has 1.5:1 Rocker Ratio.

The LT4's new valve springs are made from egg shaped wire for higher seat pressure and improved valve dynamics at higher RPM.

The big difference in the heads is the intake and exhaust ports. Both are larger with bigger radius bends. The "short side" radius of the LT4's exhaust port in particular has been increased to reduce back pressure at higher RPM,s. A throat cut just past the exhaust valve seat also opens up the exhaust port. (Unshrouding valve). The Intake port volume has increasd by 25cc. Increased from 170cc on the LT1 to 195cc for the LT4. The flow through the heads have been increased from 212CFM (Cubic feet per minute) @ 28" (711mm) (LT1) to 240CFM (LT4).

The roof was slightly lowered and the walls were moved back slightly from the valves for better breathing, ndercutting next to the exhaust valve thereby "unshrouding the valves." Revised port contours enhance air flow into and out of the engine resulting in increased fuel burning efficiency.

Combustion chambers are almost identical with a negligible .4cc increase in volume for the LT4 Combustion chambers at 54.4cc's.

Both the LT1 and the LT4 Heads accomodate 7/16" studs but the LT4 has larger 7/16 rocker studs. There are some reports of early LT4's with 10mm top threads. The LT1 studs are 3/8" on top and 7/16" bottom. GM part numbers are #3921912 for 7/16" LT4 and #1255216 for 3/8" LT1.

Shown below is a cross section comparison of the LT1 (photo A) and the LT4 (photo B) heads. The LT4 Intake port is 25cc larger than the LT1. The revised rocker cover rail is due to the taller intake port opening. Intake valve sizes are 1.94" on the LT1 and 2.00" on the LT4.

In the photo below, ote the differences in the exhaust ports on the LT1 (photo A) and the LT4 (photo B). The short side-radius offer much smoother flow and the throat cut is slightly different. Exhaust valve sizes are 1.50" (38.1mm) on the LT1 and 1.55" (39.4mm) on the LT4. Also notice the LT4's 7/16" top thread on studs vs. the 3/8" on the LT1.

The LT4 also features new composite head gaskets necessitated by higher compression ratio. Rather than the "impregnated surface" of the LT1's gaskets, he LT4's are "graphoil" with stainless steel fire rings.

A gain in compression ratio, rom 10.4:1 to 10.8:1, omes from machining the valve pockets in the pistons shallower than the LT1's.

A new top compression ring. High-speed durability tests of the engine revealed that ring flutter became a serious problem above 5,500 rpm, nd the result was excessive blow-by. To cure this, omething called a positive twist compression ring was specified. A chamfer cut into this type of ring's inside edge causes it to flex down in response to the introduction of cylinder gas pressure, eading to better sealing at higher rpm. "If you look closely at the inside edge of the ring, ou can see that there's a chamfer cut on it, nd by changing the cross-sectional area on that inside-and the properties associated with it was the end gap of the ring comes together, he ring actually takes on a slight positive twist. It is no longer perpendicular to the bore." But when cylinder gas pressure is introduced, he ring flexes down and seals better against the bore. "If you start with a ring that's flat, hen you flex, you end up with a line seal, his way you end up sealing across a broader area."

The engine's higher rpm also exceeded the LT1's fuel injector's ability to keep up, o the LT4 got larger fuel injectors rated at 3.5 grams per second (28lbs/hr), eplacing the 3.0 gram (24lbs/hr) injectors of the LT1. The larger injectors were designed to keep pace with the better breathing, igher revving engine.

The 48mm throttle body remained unchanged from the LT1, owever all LT4 equipped Corvettes (not just Z16 Grand Sports) featured a throttle body top cover plate with the words "Grand Sport" in red letters.

A specific intake manifold was cast for use with LT4 heads. Although the manifold and head intake ports do not precisely match, he manifold was cast with additional material to allow safe machining of the ports to more closely match the LT4's higher head ports. LT4 intakes were powder coated red from the factory to differentiate them from the standard LT1 manifold.

Click here for more info about the differences between LT1 and LT4 intake manifolds.

Stock LT1 has powdered metal butt link chain drive for the camshaft and water Pump. LT4 has smaller but stronger steel roller chain. Although it seems that the new chain and sprockets would reduce mass, he cam sprocket was left solid, ather than webbed, pecifically for additional mass. Increased inertia in the system reduces the tendency for cam torsion.

The crank itself was improved via something called undercutting and rolling. Undercutting is the machining of a groove into the corner of a journal. Though this would seem to weaken the crank at that point, t actually makes it stronger where tensile stress is most likely to cause sudden failure. Rolling the undercut introduces compressive stress to the area. This makes it more durable, ecause potentially catastrophic tensile stress generated during high RPM operation must first overcome the compressive stress before that area of the crank is subjected to tension. Undercutting, groove cut into the corner of a journal, ooks counterintuitive, ut makes a crankshaft stronger where tensile stress is most likely to cause failure. By undercutting and then rolling it, ompressive stress is introduced. Tensile stress during high-speed operation first has to overcome the compressive stress before there's any tension on the joint. And as tensile stress is what breaks crankshafts, ndercutting and rolling make the crankshaft stronger.

Tuned for high engine speed, lso helps reduce stress on the crankshaft. LT1 pt.# 10128489 and LT4 pt.# 12551486

These LT4 components are considerably stronger than their LT1 counterparts and resist failure at higher RPM's.

Offers improved durability over the standard LT1 crank seal.

Source for the info www.grandsportregistry.com/lt1vslt4.htm

Not to mention, his car was ordered with Factory Level III suspension, which includes the one inch lower Eibach Springs, oly bushings and Bilstien shocks. .92 to .94 G on the lateral G pad test. Most of the 100 cars built, ere level 1 and or level 2 models. This car was specially ordered in a level 3 platform, s denoted by the SLP paperwork. Which makes this car extremely, xtremely rare, specially this combo, ith the hounds tooth interior!!! The hounds tooth, eally makes it, hich is a throwback to the late 60s. Very cool!!

Highly collectible!!! No disappointments!!! However, e encourage inspection before purchase. Call!! 1-630-310-2494. This car is highly collectible, nd will be, he one to have.

1997 Chevrolet Camaro Z/28 Convertible - ONLY 8,965 ORIGINAL MILES - LAS VEGAS

1997 Chevrolet Camaro Z/28 Convertible - ONLY 8,965 ORIGINAL MILES - LAS VEGAS

1997 Chevrolet Camaro T-top low miles

1997 Chevrolet Camaro T-top low miles

1997 Chevrolet Camaro 30th Anniversary SS 29k miles 1 of 61

1997 Chevrolet Camaro 30th Anniversary SS 29k miles 1 of 61